As we move towards Industry 4.0 and the inception of the smart factory, infrastructure and connectivity have never been more important. Without the necessary speed, reliability and capacity, communication systems would become the bottleneck. Industrial settings are some of the most challenging environments to deliver such results, but we at JJ-LAPP are excited to meet these challenges head-on, with innovative products at the forefront of data transfer

The higher temperatures, oily environment and electromagnetic interference that may be present in an industrial environment all present unique challenges to data networks. Where moving machine parts or mechanical stress come into play, the demands are even tougher. At the same time, reliable data transfer is even more important in these conditions due to overall system complexity.

Take, for example, robotic operations. The core benefits offered by industrial robotics are high speed, reliability and quality, so the systems on which they are based must also deliver on these expectations. Due to the various movements required in robotic operations, cables can be subjected to high-frequency bending and torsion along with chemical exposure. Even small losses of data in these scenarios can jeopardise the outputs of an entire production line, or even human life. The stakes could not be higher.

Environmental factors and movement result in similar challenges when it comes to Ethernet requirements for machine usage, and many different types of protection class may be needed depending on that usage. Reliable communication between the machine control and the sensors or actuators in the machinery is essential to maintain uninterrupted service. Consequently, each application must be considered carefully and designed with individual attention to ensure optimum performance.

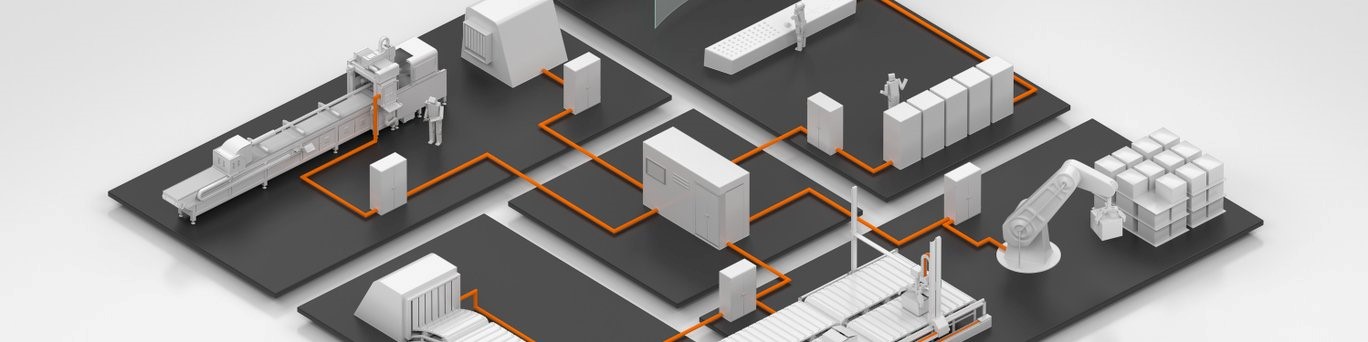

In field applications, different components are often connected in a series. This usually starts with the control cabinet, to which machinery is linked via sensors and actuators throughout the system. In every part of the chain, cables and accessories may have differing requirements in terms of resistance, functionality and environment. As with machine-system design, each element of the network must be studied and viewed in terms of its place within the whole.

In an office environment, on the other hand, the main control cabinet is the heart of the entire system, connecting the office-level and individual machine controls. While physical stresses are less of an issue, there is great demand for data speed and reliability under potentially high electromagnetic interference.

In the wider office network, all the individual elements depend on a connection with one another and the Internet. Such extensive networks require components that deliver safety and security as well as performance. Longer distance, building-to-building connections also necessitate high speeds and often make use of glass fibre (fibre optic) cables.

With industrial advances continuing apace, ensuring that your systems are built for future success, from the foundations upwards, is critical for long-term results. JJ-LAPP’s experience and expertise, along with our innovative product range, specifically developed with each application in mind, make us the best team to advise on building high-performance systems for both today and tomorrow.

Get in touch with us to ensure your future systems take full advantage of all today’s innovations.

Contact us to find out whether your networks could benefit from our expertise.