Factory Automation Network

Reliable high speed networking solutions for automation, control and industrial environments

Reliable data flow is critical in modern automated factories

Factory automation demands high data volumes, real time communication, and seamless connectivity across harsh industrial environments. From sensors and actuators on the production floor to PLCs and enterprise systems, stable and secure data transmission is essential for maintaining efficiency and preventing downtime.

End-to-end networking solutions for your operations

We deliver complete factory automation networking systems including industrial cables, connectors, switches, fieldbus components, and distribution boxes. Every product is engineered for vibration, temperature variation, and demanding industrial conditions, ensuring consistent communication across your entire automation architecture.

Where This Solution Is Needed

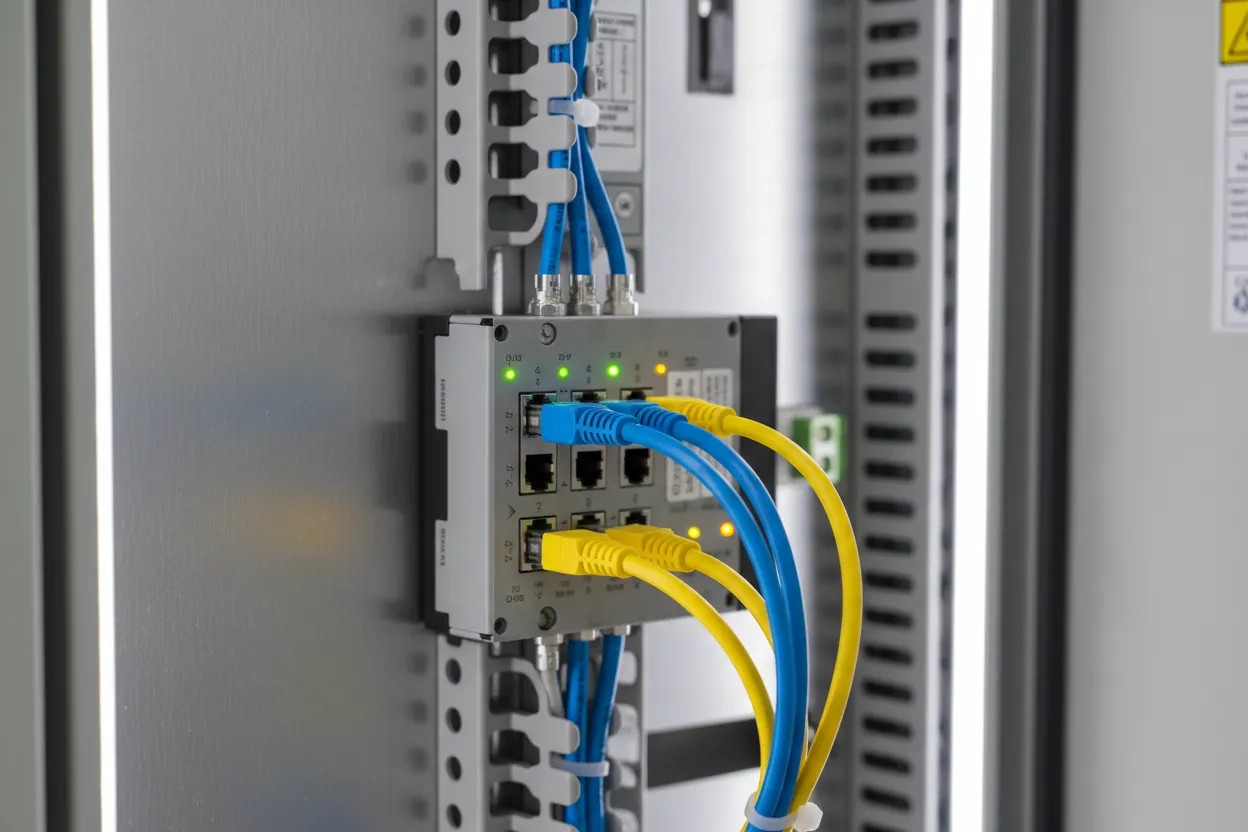

01 Machine and Robot Connectivity

High-speed communication for controllers, robots, drives and vision systems.

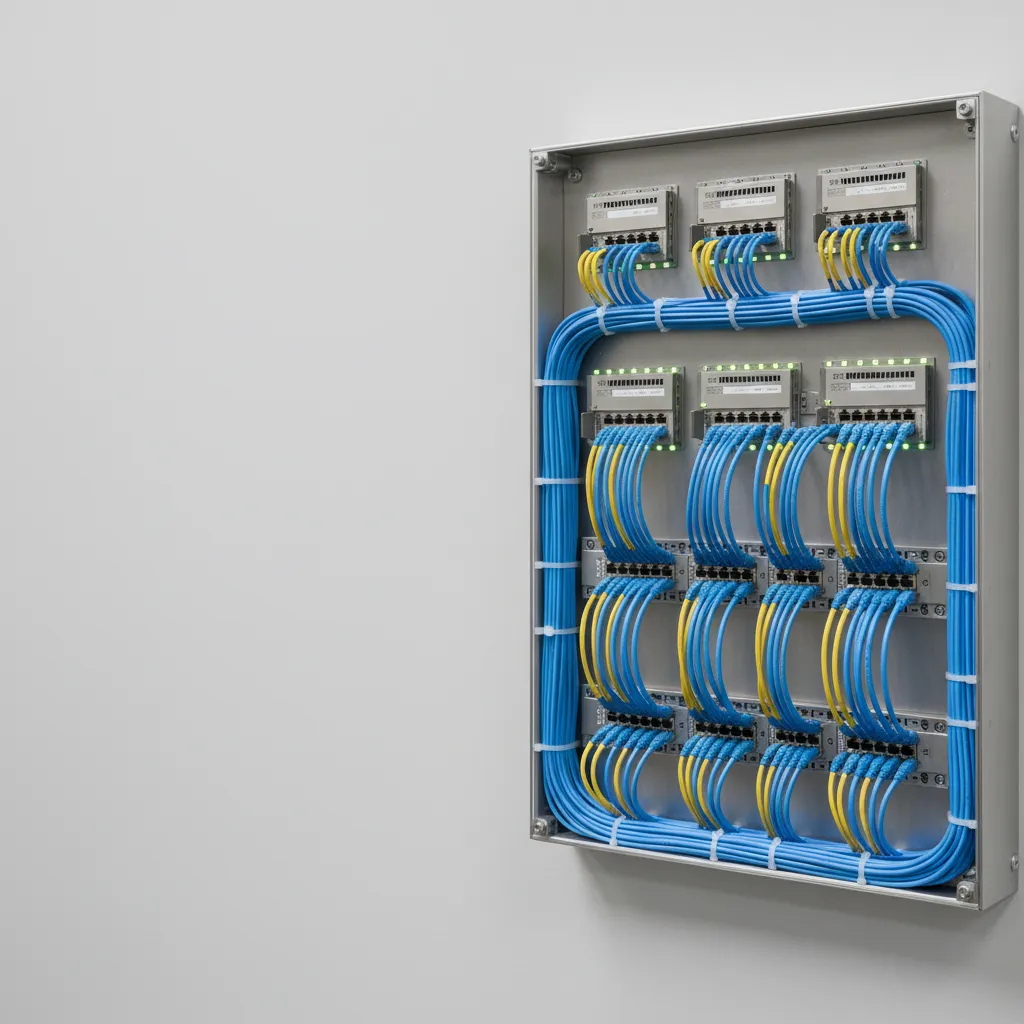

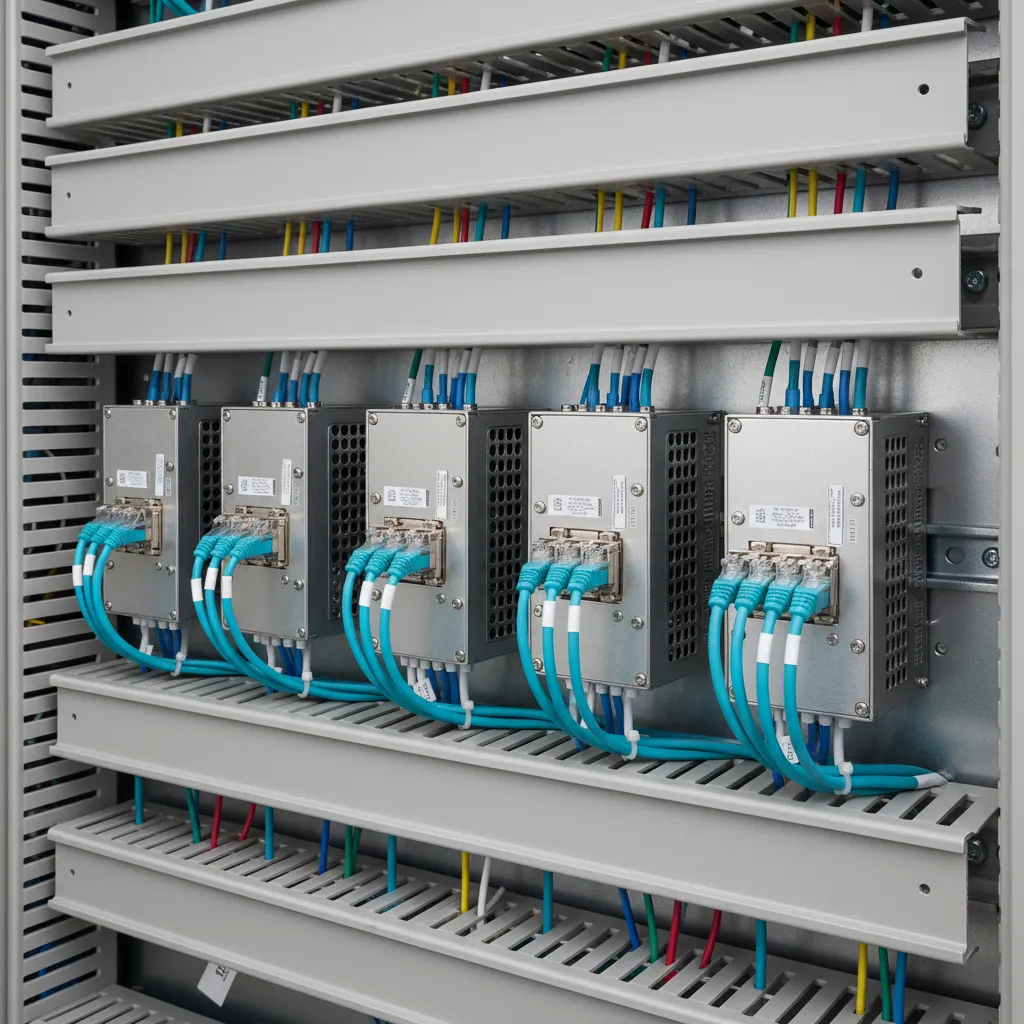

02 Control Cabinets and Panels

Reliable structured wiring and Ethernet distribution inside industrial cabinets.

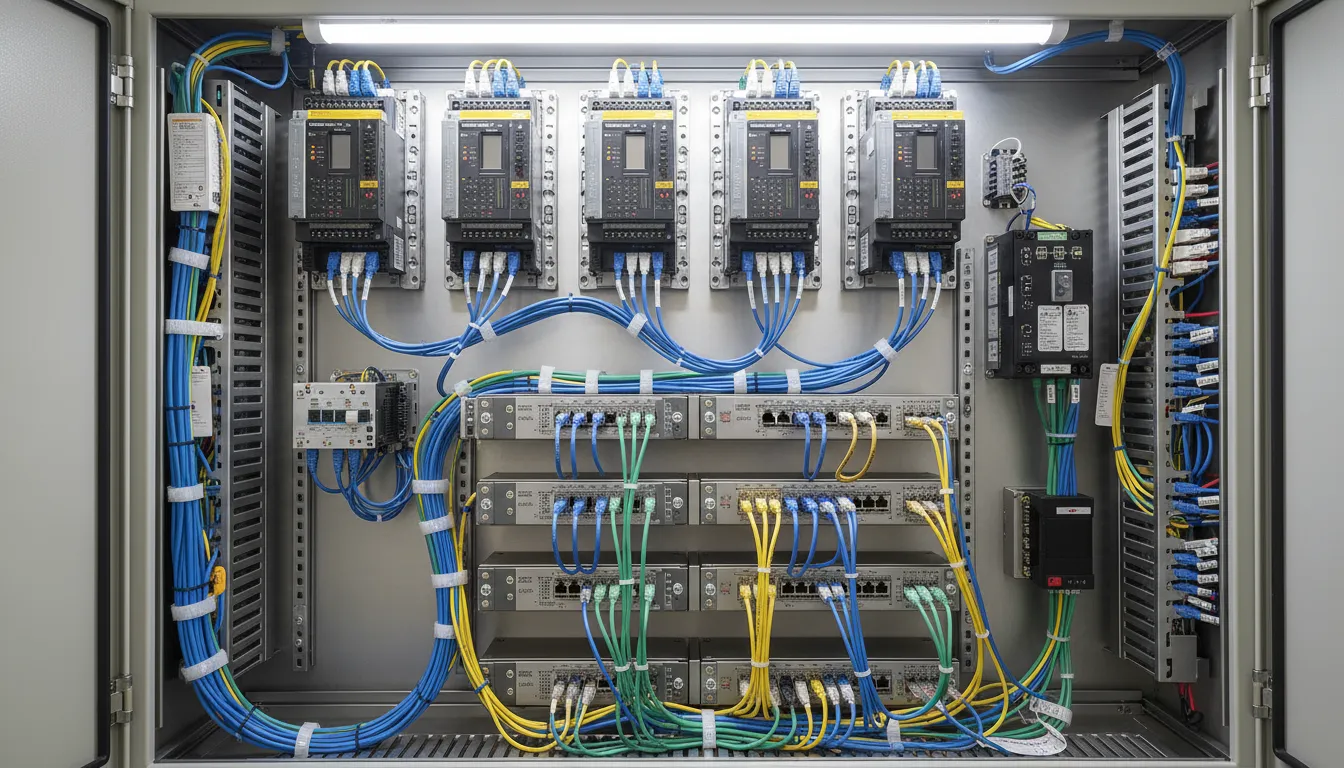

03 Production and Plant Networks

Robust networking for large-scale automation lines and harsh environments

Applications

Select the right industrial communication setup for your equipment and environment to ensure reliable, high-performance data flow.

Sensor & Actuator Level Communication

Challenge:

Production lines depend on accurate real time signals from sensors and actuators. Noise, vibration and harsh environments can disrupt communication and slow down cycle times.

LAPP Solution:

Durable sensor/actuator cables, fieldbus lines and M8/M12 connectivity designed for reliable data and power transmission across demanding factory environments.

Control & PLC Networks

Challenge:

PLCs, robotic controllers and HMIs require fast, deterministic communication with machines and devices to maintain stable automation performance.

LAPP Solution:

End to end networking for control systems including industrial Ethernet, fieldbus connectivity, hybrid power-and-data cables and cabinet rated communication lines.

Plant Backbone & Long-Distance Links

Challenge:

Factory networks must support large data volumes, long runs, and integration between machines, control rooms and enterprise systems.

LAPP Solution:

High bandwidth backbone solutions with industrial switches, long-distance cabling and robust connectors supporting automation, monitoring and plant-wide communication.

Why LAPP for Factory Automation Networks

Interoperable by Design

Built to integrate seamlessly with PLCs, sensors, drives and industrial network devices across fieldbus and Ethernet based automation systems.

Certified for Performance

Engineered for reliable communication and safety standards, ensuring consistent operation in demanding factory and production environments.

Ready for Deployment

Delivered pre-tested and optimized for fast installation, supporting long term performance in harsh industrial conditions.

Trusted Quality

Backed by the LAPP Group’s decades of innovation in industrial connectivity and automation technology.

Durability

Efficiency

Flexibility

Protection

Project-Ready: Standards, Approvals & Delivery

Interoperable by Design

Compatible with automation systems and motion control equipment.

Certified for Performance

Meets international standards for material strength and environmental safety.

Ready to Install

Modular assembly options available for fast installation and maintenance.