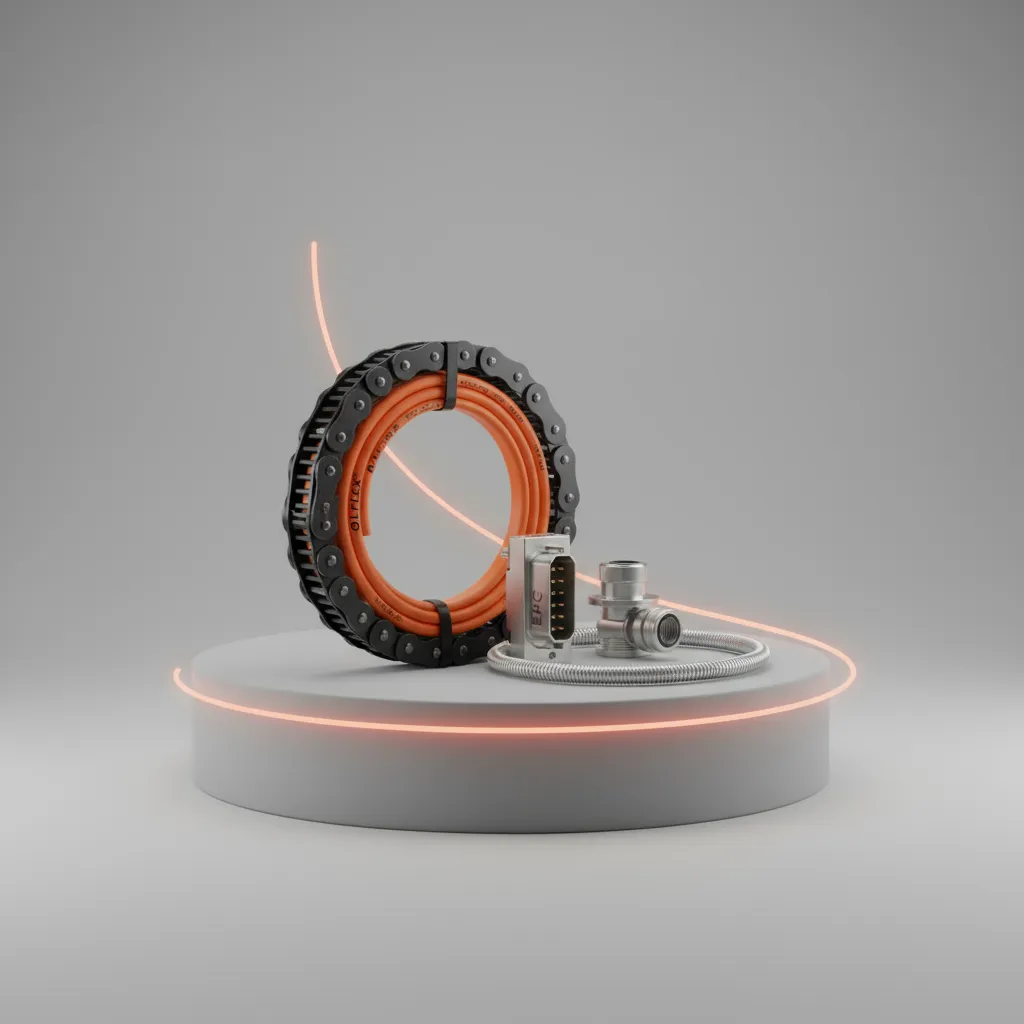

Ready-to-Install Cable Chains & Harnessing for Intralogistics

Cut install time, reduce suppliers, and run reliably with LAPP-engineered assemblies — designed, built and delivered by LAPP across ASEAN.

Extending the life of cables and wires is crucial in modern industries

Pre-assembled cable chains and cable chain systems from LAPP protect moving cables, minimise downtime and lift productivity. By selecting the right combination of chain, bend radius and matched LAPP components — ÖLFLEX® power/control, UNITRONIC®/ETHERLINE® data, EPIC® connectors, SKINTOP® glands and SILVYN® protection — you avoid on-site errors, standardise builds, and cut maintenance costs over the system l

Make it easy on yourself

Choose from standard pre-assembled chains for immediate installation, or have our engineers configure a custom set to your duty cycle (travel length, speed, cycles, environment). Every assembly arrives labelled, documented and continuity-tested. This true “plug & play” approach shortens installation, reduces contractor hours, and keeps projects on schedule with fewer disruptions.

Where Cable Chains Are Used

01 Stacker Cranes (ASRS)

Pre-assembled chains for vertical and horizontal travel. Matched ÖLFLEX® power/control and UNITRONIC®/ETHERLINE® data with EPIC® and SKINTOP® terminations enable faster commissioning, reliable bend radii and fewer failures in service.

02 Conveyors & Sortation

Plug-and-play harnessing for rollers, belts and sorters. Standardised interfaces keep connectivity consistent and enable rapid reconfiguration, JIT builds and easier maintenance with labelled connectors and documented assemblies on site.

03 AMR & AGV

Compact, EMC-optimised looms and chain sections for robots. Custom routing reduces weight, improves reliability over high duty cycles, and simplifies service with labelling and protected bend radii in spaces.

Applications

Select the right cable chain and harness set for your duty cycle and environment.

ASRS (Stacker Cranes & Shuttles)

Challenge:

Long vertical runs, high speeds/cycles, reliable bend radius.

LAPP Solution:

Lightweight plastic chains with guide troughs, matched ÖLFLEX® power + UNITRONIC®/ETHERLINE® data, EPIC®/SKINTOP® terminations, labelled and tested for fast commissioning.

Conveyors & Sortation

Challenge:

Continuous motion, vibration, rapid reconfiguration across modules.

LAPP Solution:

Modular, plug-and-play harness sets with standardised interfaces; reinforced chains with guide channels; documentation for quick line changes and maintenance.

Gantry Cranes & Long Travel

Challenge:

Long travel distances, side loads and cable sag.

LAPP Solution:

Reinforced chain designs with guide troughs and gliders; optimised fill and bend radius; pre-terminated sections for stable linear motion and easier installs.

Particle limits and low noise requirements.

Challenge:

Particle limits and low noise requirements.

LAPP Solution:

Low-friction, low-abrasion plastic chains; cleanroom-tested materials; sealed terminations and labelled looms to simplify audits.

Why LAPP for Pre-assembled Cable Chains

Plug-and-play installation

Pre-assembled, labelled, continuity-tested chains reduce on-site labour and errors.

One system, one supplier

ÖLFLEX® power/control, UNITRONIC®/ETHERLINE®/HITRONIC®, EPIC® connectors, SKINTOP® glands, SILVYN® protection.

Compliance & documentation

UL/EN/CPR options, LSZH/HFFR where needed; BoM, drawings and test reports provided.

ASEAN design-in & delivery

Local engineering, regional stock, JIT delivery and after-sales across Southeast Asia.

Duty-tested

Approvals-ready

Plug & play

ASEAN reach

Project-Ready: Standards, Approvals & Delivery

Interoperable by Design

Works with common PLCs, drives and motion systems. Matched LAPP cables, connectors and glands for clean integration.

Certified for Performance

UL / EN / CPR (Euroclass B2ca–Eca) options; RoHS / REACH compliant; LSZH/HFFR variants available on request.

Ready to Install

Pre-assembled, labelled and continuity-tested. Supplied with BoM, drawings and basic test report to speed site hand-over.

Standards

ISO 9001

ISO 14001

UL / CSA

EN 50575 (CPR)

DIN EN 61800-5-1

EN/IEC 60204-1

CE