Cable Glands that Seal, Strain-relieve and Pass Audits

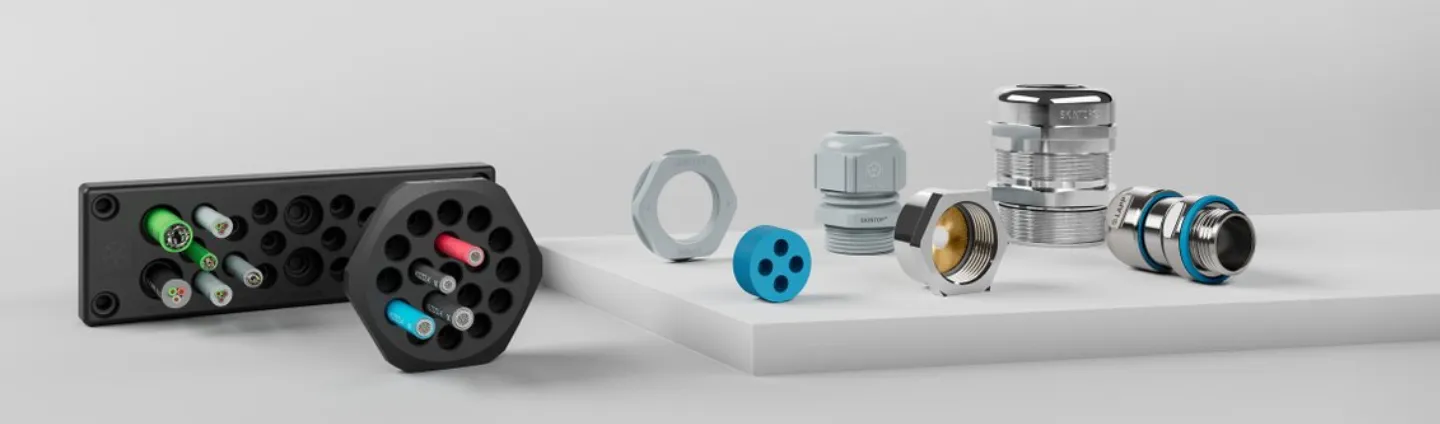

IP66/68/69K, EMC and HYGIENIC options in plastic, brass and stainless steel

Browse featured cables

Choose your assembly type and application needs to see parts on the eShop with filters applied.

SKINTOP® – The Handy Cable Glands

SKINTOP® cable glands ensure a secure connection in a matter of seconds. The universal systems are simple, perfect and easy to install: simply insert the cable, close and go. The cable is securely fixed, centred and hermetically sealed.

Discover Our Cable Glands

Cable glands allow cables to be inserted into a housing, make it possible to securely seal both the cables and the housing and achieve cable strain relief. They protect the interior of the housing from harmful environmental influences such as dust and moisture. Our product range contains single-entries, multi-entries for multiple cables, as well as accessories and tools for assembling the glands.

Where cable glands are used

01 Single-entries

General sealing and strain relief for enclosures

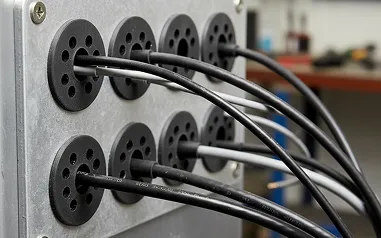

02 Multi-entries / Plates

Space-saving entries for multiple cables

03 EMC / HYGIENIC

360° shielding or smooth, easy-to-clean stainless

Which essential requirements must a cable gland meet?