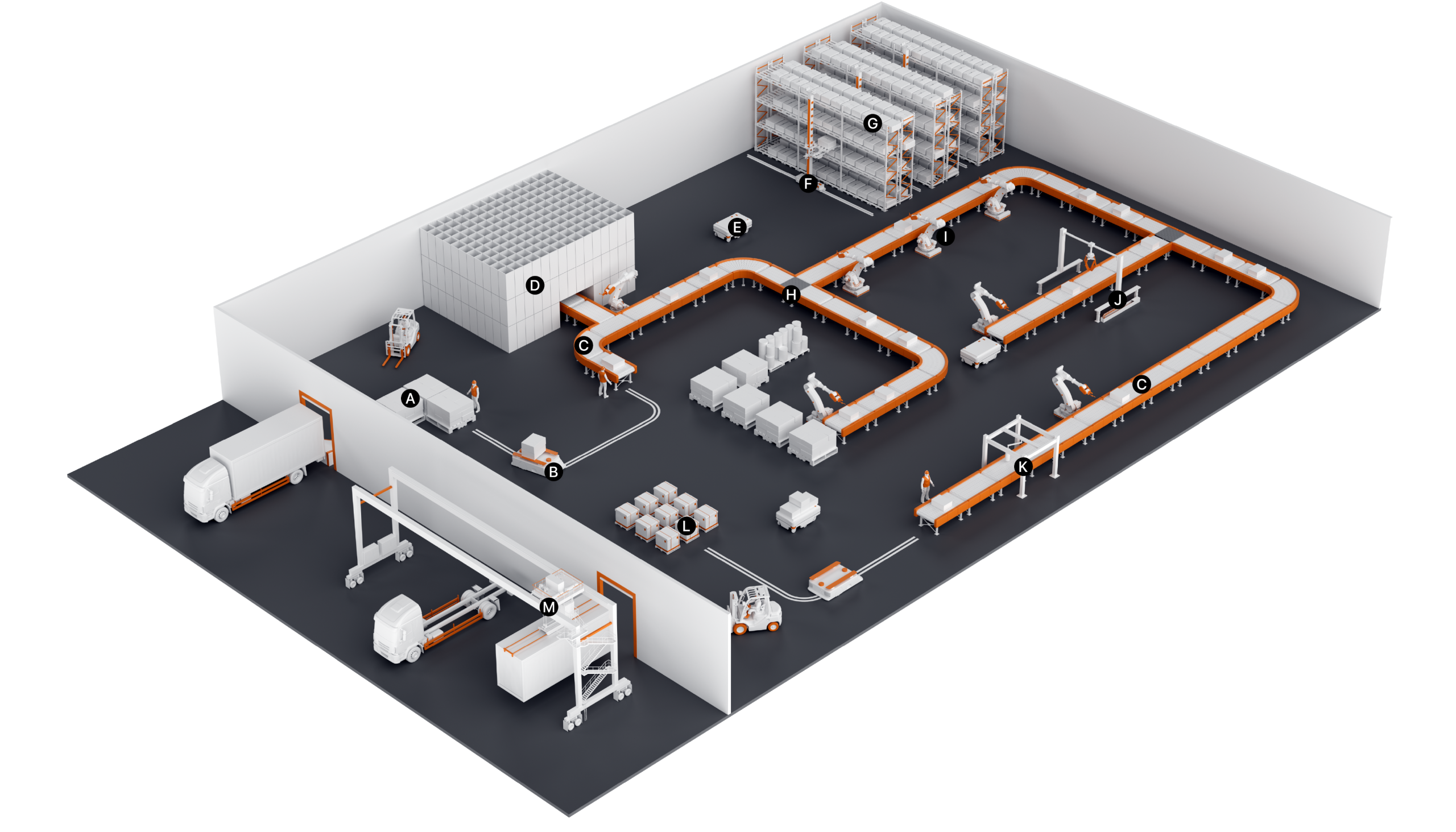

Intralogistics Connectivity for ASRS,

Conveyors & AMRs—built for ASEAN

warehouses.

Standardised, certified cables, ready-made harnesses and on-site support.

Faster installs, less downtime, simpler BOMs.

Overview

Discover JJ-LAPP Intralogistics Solutions

JJ-LAPP helps warehouses and factories across ASEAN optimise intralogistics by connecting the systems behind modern operations — ASRS, conveyors, sorters, AMRs/AGVs, cranes & hoists, small-parts storage and site infrastructure. Our solutions are fully compatible across standard Ethernet and fieldbus environments, so they slot cleanly into your existing controls architecture.

Built on proven LAPP families — ÖLFLEX® power/control, ETHERLINE® & UNITRONIC® data, HITRONIC® fibre, EPIC® connectors, SKINTOP® and SILVYN® protection — you get standardised, certified building blocks with the right options for your site: deep-freeze to –40 °C, UL/CSA and CPR classes, halogen-free and high-flex for cable-chain motion.

Delivery is end-to-end: ready-made harnesses and cable chains, design-in support and last-mile logistics keep installs fast and BOMs simple, reducing risk and downtime.

Plug-and-play assemblies, certified parts, and fast last-mile delivery across SEA.

Three Sub-Areas of Intralogistics

Applications

Intralogistics applications put cables, connectors, and glands under constant stress: flexing, torsion, vibration, heat, and EMI. Each station faces a different failure mode, and choosing the right product is critical to avoid downtime. The eight applications below show the dominant stresses and the proven LAPP solutions that keep systems running reliably.

That 60-Minute Line Stop? It Started With One Weak Cable

- Spot hidden weak links in under five minutes

- Know the real downtime cost for your line, in $/ID

- Pick the right cable spec forst-time, every time

Why JJ-LAPP for Intralogistics

Standardised, certified connectivity for ASRS, conveyors, AMRs and robotics. Plug-and-play assemblies and last-mile support help you install faster, run longer, and cut cost.

Enhanced Uptime

Pre‑tested harnesses and low‑loss cables minimise downtime.

Scalable Infrastructure

Modular cabling systems adapt to hyperscale growth.

Compliance Ready

CPR, UL/CSA and ISO‑aligned solutions support audits.

Operational Efficiency

JIT delivery and engineered harnessing reduce installation risks and costs

Why JJ-LAPP for Intralogistics

Standardised, certified connectivity for ASRS, conveyors, AMRs and robotics.

Plug-and-play assemblies and last-mile support help you install faster, run longer, and cut cost.

- Enhanced Efficiency — Pre-terminated harnesses and cable chains slash install and fault-finding time.

- Cost Savings — One approved spec across sites reduces spares, vendors and maintenance hours.

- Scalability — Works across PROFINET, EtherCAT, EtherNet/IP and ASi, so lines and sites scale easily.

- Uptime & Accuracy — Reliable power/data minimises errors and prevents unplanned stops.

Enhanced Efficiency

Streamline internal processes for optimal performance.

Cost Savings

Reduce operational expenses through streamlined logistics.

Scalability

Solutions tailored to grow with your business.

Improved Customer Satisfaction

Ensure timely and accurate order fulfillment for happy customers.

Project-Ready: Standards, Approvals & Delivery

Interoperable by Design

Works across PROFINET, EtherCAT, EtherNet/IP and ASi, so you integrate without lock-in.

Certified for Tough Sites

Options for –40 °C deep-freeze, UL/CSA, CPR (B2ca–Eca) and halogen-free/LSZH.

Plug-and-Play & Last-Mile

Ready-made cable chains and harnessing with just-in-time (JIT) delivery and on-site coordination.

Ready to Spec Your Intralogistics Connectivity?

Engineer-led guidance for ASRS, conveyors, AMRs and robotics with

certified, install-ready solutions.

eShop: Intralogistics Products & Solutions

Browse stocked JJ-LAPP parts for ASRS, conveyors, AMRs and robotics. Download the Intralogistics Survival Kit→

Speak to an Engineer

Need help speccing cables for ASRS, conveyors, AMRs or robotics? Get an install-ready recommendation from our team.