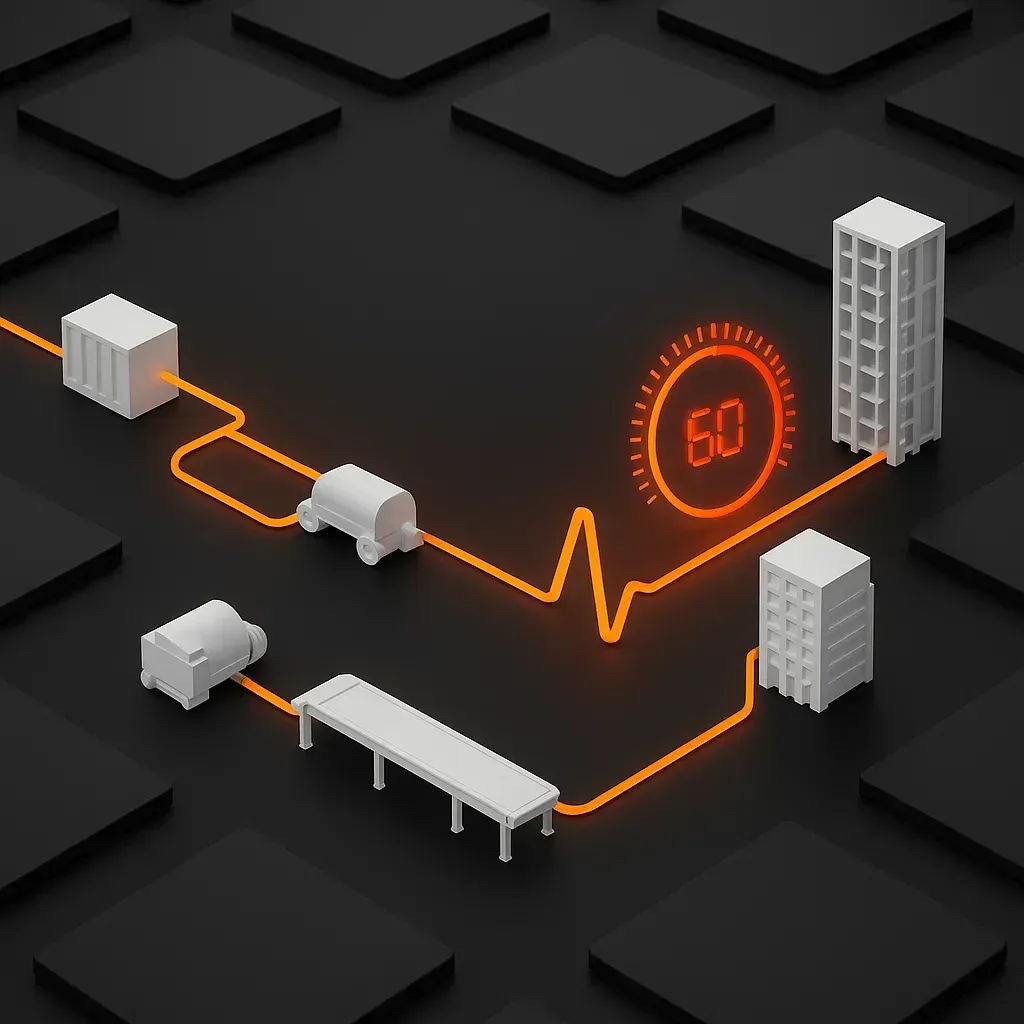

That 60-minute line stop? It started with one weak cable

- Spot hidden weak links in under five minutes.

- Know the real downtime cost for your line, in €/$/IDR.

- Pick the right cable spec first time, every time.

60-Second Connectivity-Failure Self-Audit

Answer 6 quick questions to get an instant risk score. It pinpoints your top vulnerability so you know exactly what to fix first.

- Benchmark your system against 8 critical failure points in ~60 seconds.

- Get an instant risk score that highlights your #1 vulnerability.

- Move from reactive repairs to proactive prevention by spotting hidden risks before they stop your line.

Your Complete Toolkit for Predicting & Preventing Failure

A single connectivity failures can cost thousands. Use our 60-second calculator to see your specific financial impact

Engineering Spec Pack

- The master Excel with field-tested specs for each intralogistics application. Pick the right cables, glands and accessories in minutes.

- See Main Challenges → Impact → Top Seller → Key Features for every pack in one place.

- Eliminate guesswork with the exact LAPP part families and EMC notes engineers use on site.

- Work faster — copy specs straight into RFQs, drawings and BOMs.

Limited Offer

On-Site Engineering Consultation

- For teams that need a deeper analysis, we’re offering a complimentary On-Site Engineering Consultation during this pilot phase.

- This is more than just a health check. One of our connectivity specialists will partner with your team on-site to:

- Provide a second set of expert eyes on your most critical applications.

- Share best practices for cable routing and management in high-cycle environments.

- Identify subtle risks related to strain, torsion, and EMC interference.

You get a confidential report and actionable advice, at no cost.

Download the Intralogistics Kit to Qualify

From Audit to Action: A Real-World Scenario

How does the kit work in practice? Imagine an engineer dealing with intermittent faults on a critical crane.

First, he uses the Downtime Calculator to see the financial impact. The “minor” faults add up to more than $12,000/month in lost throughput.

Next, with that cost proof, he runs the 60-second Connectivity-Failure Audit to pinpoint the root cause. The results flag a high risk: the current cables aren’t chain-rated for constant motion.

Finally, he opens the Engineering Spec Pack (Excel), selects the correct ÖLFLEX® crane cable and EMC gland for the application, and prepares the justification.

The result: Immediate budget approval, weak link replaced, and a catastrophic failure avoided—turning a hidden risk into a documented win.

Frequently Asked Questions