M12 L‑Code: The Compact Power Standard for AGVs & Cobots

Your design team has spent months shaving grams and millimetres off your new AGV prototype. It’s sleek, purposeful, and efficient—but one component stands out, literally. The bulky, 7/8‑inch power connector forces an awkward bulge, creating a snag point that spoils the design and compromises the housing.

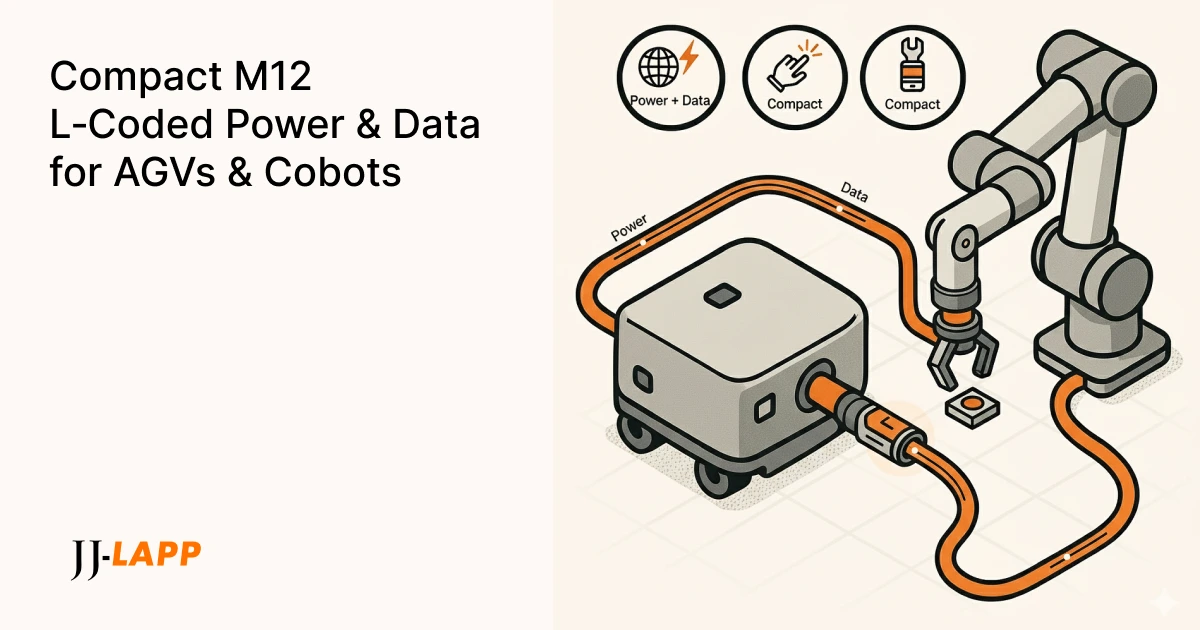

In mobile robotics, where every millimetre counts, this is more than an aesthetic issue; it’s a potential failure point. Across Southeast Asia’s fast‑growing industrial automation scene, engineering teams are pushing for lighter, tighter AGVs and cobots. The answer isn’t a radical new invention, but a smart, globally standardized one: M12 L‑coded power. Here’s how it helps you deliver serious DC power in a much smaller footprint, without compromising reliability or serviceability.

What is M12 L‑Code? The New DC Power Standard for Robotics

Traditionally, DC power for I/O blocks, sensors, and small drives used legacy 7/8‑inch connectors. The M12 L‑code (defined in the IEC 61076‑2‑111 standard) is its modern replacement. It uses a compact M12 interface specifically designed for low‑voltage, high‑current DC applications—typically up to 63 V DC / 16 A, depending on the connector and conductor size.

Critically, this high-current M12 connector is the recommended 24 V field‑power interface in the official PROFINET Cabling & Interconnection Guideline, making adoption straightforward and ensuring interoperability in modern automated cells.

M12 L-Code vs. 7/8-Inch: A Clear Upgrade for Industrial Automation

The shift from 7/8-inch to M12 L-code is a fundamental change in design philosophy for robotics power solutions. The difference is stark:

| Feature | 7/8-Inch Connector | M12 L-Coded Connector | Impact on Your Design |

| Footprint | ~22 mm Diameter | 12 mm Diameter | >50% Reduction in Footprint: Enables denser I/O panels and mounting in tight spaces like cobot joints. |

| Power Delivery | Typically up to 10 A | Up to 16 A | 60% More Current: Power more demanding components like small servo drives or sensor clusters from a single, compact point. |

| Standardization | Older industrial standard | IEC 61076-2-111, PROFINET | Global Interoperability: Source components from multiple vendors with guaranteed compatibility, simplifying international service. |

| Vibration Resistance | Good | Excellent | Greater Reliability: Threaded M12 coupling is inherently resistant to loosening from constant motion and vibration in mobile applications. |

Four Key Advantages of M12 L-Code in Robotics Design

- High Power Density You get 7/8‑class power in a classic M12 form factor. This is a significantly smaller panel footprint that suits low‑profile AGVs and compact cobot joints. Less bulk also improves weight distribution and makes maintenance access far easier.

- Secure Performance Under Motion A threaded, locking M12 coupling is built to resist vibration‑induced loosening—a critical feature for mobile robotics. With ingress protection up to IP67 when properly mated, this reliable power connector performs in dusty or wet environments.

- Global, Standardised Parts As an IEC interface referenced by PROFINET, M12 L‑code ensures multi‑vendor interoperability. This simplifies sourcing, reduces inventory complexity, and streamlines field service across ASEAN and beyond.

- Cleaner Harnesses with Hybrid Runs Where space and weight are paramount, you can route a single hybrid cable carrying power and data cores in one jacket. This allows you to terminate to M12 L (power) and M12 D/X (data) at the device, cutting the number of cables and reducing mass.

Building Your M12 L-Code Solution with LAPP

- Connectors: EPIC® POWER M12 L‑coded connectors and cordsets provide compact, high‑current DC with robust metal housings and 360° shielding for complete EMC control.

- Distribution & Accessories: For compact field‑power breakouts, explore our range of distribution blocks and related components in the Sensor/Actuator & Fieldbus Distribution category.

Installation Best Practices for a Reliable M12 L-Code Connection

A connector is only as good as its termination. To ensure maximum performance and a reliable IP seal, follow these critical guidelines:

- Pin‑out (4+PE): The design uses two L+ pins and two L- pins to share the current load, which is key to achieving the 16 A rating while reducing heat.

- Torque: Always tighten the coupling to the datasheet value (typically ≈0.6 Nm). This precise torque compresses the O-ring to create a watertight seal.

- Conductor Size: Voltage drop is the silent killer in low-voltage systems. Size your cable conductors for the current and run length; 1.5–2.5 mm² is common for 16 A short runs.

- EMC: Maintain 360° shield continuity from the cable into the device housing to protect against electrical noise.

M12 L-Code Connectors: Frequently Asked Questions (FAQ)

What’s the difference between M12 A, B, D, X, and L-coding? The codes prevent mis-mating. A-code is for sensors, D is for 100 Mb/s Ethernet, and X is for multi-gigabit Ethernet. L-code is specifically for DC power.

Is M12 L‑coded PROFINET‑compliant? Yes. It’s officially listed in the PROFINET guideline as the recommended 24 V field‑power connector.

Can I use any cable with M12 L‑coded plugs? No. You must use a cable with conductors correctly sized for the current (e.g., 1.5–2.5 mm² for 16 A runs) to avoid heat, voltage drop, and premature failure.

Miniaturise Without Compromise

In Southeast Asia’s competitive robotics market, the M12 L‑code standard helps you build smaller, lighter, and easier‑to‑service AGVs and cobots without sacrificing power delivery. By adopting a global standard, your team can innovate faster with parts you can source locally and trust completely.Ready to shrink your power footprint? Explore our M12 connector options or ask about our hybrid cable solutions. Contact LAPP