LSZH Cables: Boost Safety in Building Infrastructure

What happens when the very cables powering your ‘smart’ building become its biggest fire risk? HVAC, lighting, security—these essential systems rely heavily on reliable connectivity. But with greater connectivity comes greater responsibility, especially regarding fire safety. Enter LSZH cables—low smoke, zero halogen cables designed specifically to minimize risks in emergencies.

Understanding LSZH Cables

LSZH ≠ fire‑resistant. These jackets limit smoke and toxic gases but do not guarantee circuit integrity under flame. Pair them with certified fire‑resistant cables where operation during a blaze is mission‑critical.

The acronym “LSZH” stands for Low Smoke, Zero Halogen (also called LSF or HFFR in some regional specifications). In simpler terms, these cables are specially manufactured to produce minimal smoke and no harmful halogens when exposed to fire. Unlike conventional PVC cables, which emit dense, toxic smoke containing hydrochloric acid (HCl), LSZH cables release significantly lower smoke levels, preserving visibility and reducing toxic gas inhalation during emergencies.

LSZH cables consist primarily of halogen‑free polyethylene compounds and are tested thoroughly against three key standards: IEC 60332‑3‑24 – flame‑spread on bundled cables, IEC 60754‑1/2 – halogen‑acid content, and IEC 61034‑2 – smoke‑density.

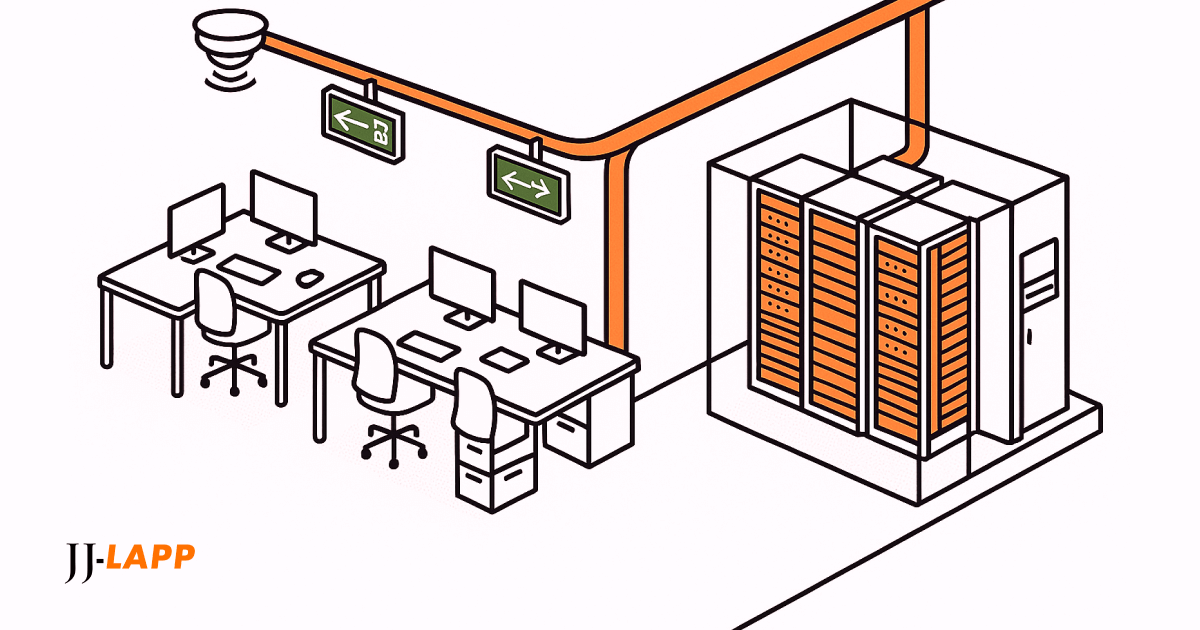

Commonly found in densely populated or critical areas—such as data centers, hospitals, metro systems, or multi-storey hotels—these cables address two critical needs: protecting human lives and safeguarding sensitive electronic systems.

When compared side‑by‑side with traditional PVC, LSZH emits < 20 % of the smoke density under identical test conditions—dramatically boosting visibility for evacuees (IEC 61034 test data).

How LSZH Cables Enhance Building Infrastructure Safety

When fire breaks out, survival often hinges on how quickly and clearly occupants can evacuate. Here, LSZH cables shine by significantly reducing smoke blockage and toxic fumes, thereby increasing visibility and extending escape windows.

In Southeast Asia, regulatory momentum is rapidly shifting toward LSZH. Two standout examples:

| Country | Status | Key Clause |

| Singapore | Mandatory for rapid‑transit & life‑safety circuits | SCDF Fire Code 2022 §9.1A, Note 3 |

| Malaysia | Strongly recommended for safety circuits in high‑rise buildings | BOMBA FTO 201 (2021) §10.5 (b) |

| Indonesia | Draft guidance proposes LSZH on all escape routes | Draft SNI 04‑22xx (Ministry PUPR) |

Another big plus of LSZH is the reduced corrosion of sensitive electronic components during fires—helps keep BAS hardware working when it matters most. As buildings lean harder on digital control rooms and dense risers, LSZH is fast becoming the safe default.

Choosing the Right LSZH Solutions for Your Facility

Building Infrastructure involves multiple cable types—data cables for communication, power cables for electricity supply, and control cables for operational signals. Fortunately, reputable brands such as JJ-LAPP offer comprehensive ranges specifically tailored for automation systems:

- Data Cables (CAT 6/6A) for network reliability.

- Power & Control Cables (e.g., ÖLFLEX® CLASS LSF) ensuring robust energy delivery.

- Bus Systems (e.g., UNITRONIC® BUS LSZH) keeping signals safe.

Each type supports a variety of building-Infrastructure setups—from HVAC controls to security cameras and lighting systems—and is available in LSZH versions such as ÖLFLEX® CLASS LSF power & control cables and UNITRONIC® BUS LSZH data cables.

Practical Steps to Implement LSZH in Your Building

Swapping to LSZH doesn’t have to be complicated—and the maths is straightforward. A typical project pays a 15–30 % premium for LSZH over PVC. Industry downtime studies indicate that the cost of a single smoke‑driven evacuation can easily outstrip this premium—one avoided incident is often enough to recoup the investment…. Here’s a straightforward approach:

- Assess Fire Risk Areas: Identify critical zones such as escape routes, enclosed spaces, and areas housing essential equipment.

- Understand Local Regulations: Familiarise yourself with local fire codes like Singapore SCDF guidelines or Malaysia’s BOMBA recommendations.

- Plan Your Cable Management: Consider protective conduits and clearly label LSZH cables using reliable identification systems, such as Fox-Flo® cable labels, to preserve cable integrity and simplify future maintenance.

Choose Reliable Suppliers: Always demand third-party test reports demonstrating compliance with IEC 60332-3, IEC 60754, and IEC 61034 standards. Suppliers such as JJ-LAPP clearly present these certifications, ensuring that your investment is genuinely reducing risk.

Common Questions and Concerns (FAQs)

Do LSZH cables significantly increase project costs?

LSZH cables typically cost around 15‑30 % more up‑front than PVC. Yet industry downtime modelling shows that avoiding a single smoke‑driven evacuation can repay the LSZH premium several times over. Thus, the total cost of ownership (TCO) of LSZH cables is substantially lower when factoring in safety, liability, and potential downtime costs.

Are LSZH cables mandatory in all new ASEAN buildings?

Not universally. Currently, they are mandatory in specific applications in countries like Singapore, especially for critical systems. However, Malaysia and Indonesia recommend LSZH for life-safety circuits and emergency escape routes but still permit PVC in less critical areas. Nevertheless, with the increasing reliance on digital automation, LSZH is quickly becoming a standard preference due to its enhanced safety profile.

Are LSZH cables less durable than PVC cables?

LSZH cables deliver equivalent electrical performance to PVC cables but can be slightly less mechanically rugged. For installations, this simply means avoiding overly tight bends or excessive tension during cable pulling to ensure optimal cable integrity and longevity.

Conclusion: Safer Today, Prepared for Tomorrow

In modern automated buildings, fire safety is paramount. LSZH cables slash toxic smoke, keep escape routes visible, and shield sensitive automation hardware. For building owners, integrators, and developers, choosing LSZH isn’t just about ticking a compliance box—it’s proactive risk management and a future‑proof investment.

Quick next steps for facility managers

- Audit critical paths: Walk each riser and escape corridor—flag any remaining PVC runs.

- Request certificates: Ask suppliers for IEC 60332‑3, IEC 60754, and IEC 61034 test sheets before purchase.

- Label & segregate: Use LSZH‑rated markers so maintenance crews spot safety circuits at a glance.

Train the team: Brief technicians on bend‑radius and pull‑tension limits to maximise service life.

Ready to enhance safety in your Building Infrastructure systems? Explore JJ‑LAPP’s LSZH cable range or contact us for a compliance walkthrough tailored to your project.