A Guide to Torsion-Rated Ethernet & Fibre Cables for Robotic Automation

Your new machine‑vision‑guided robot in Indonesia works perfectly in testing, but on the factory floor, it randomly mispicks parts, causing costly downtime. The camera is fine, the software is fine. The hidden culprit? A standard Ethernet cable whose internal geometry is being slowly deformed by the robot’s constant twisting, corrupting critical image data via signal reflections and noise.

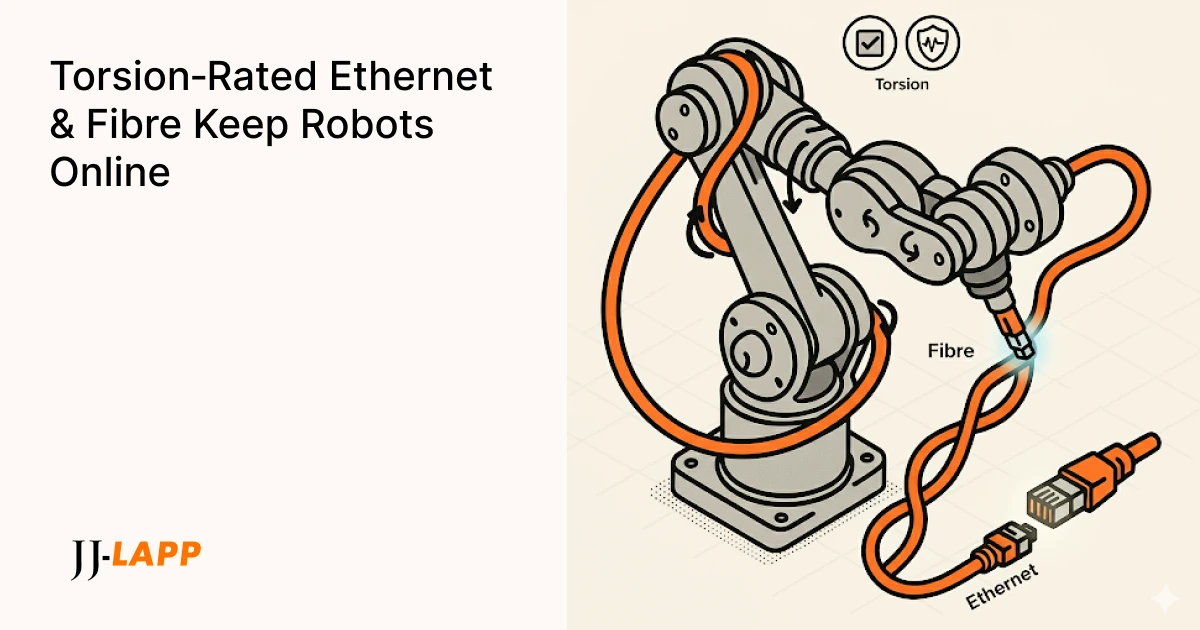

In a modern smart factory, a robot’s data link is its lifeline. Intermittent dropouts and packet loss caused by cable torsion are a nightmare to troubleshoot and can seriously impact product quality. This guide explains how the twisting motion of a 6‑axis robot degrades standard data cables and shows why specifying a torsion‑rated Ethernet or fibre cable is the only reliable fix.

Why Standard Cables Fail: How Torsion Kills Data Signals

A robotic arm’s constant clockwise and anti-clockwise twisting subjects its cabling to a brutal mechanical load. Torsion resistance for industrial cables is specified in degrees per metre (°/m) and validated over millions of test cycles to ensure data integrity.

Copper Ethernet: Impedance Mismatch & Crosstalk

High‑speed twisted‑pair cabling relies on precise internal geometry to maintain its ~100‑ohm characteristic impedance. Mechanical deformation from torsion alters that geometry, causing an impedance mismatch. This leads to higher signal reflection (return loss), which causes bit‑errors and forces data re-transmissions. As Fluke Networks explains, poor return loss is a classic sign of physical cable damage. This deformation can also increase crosstalk between pairs, compounding the errors.

Fibre Optics: Attenuation from Bending

While immune to EMI, fibre optic cable is sensitive to physical stress. Torsion introduces micro-bends and tight radii that allow light to escape the core, increasing signal loss (attenuation). To combat this, torsion-rated cables use robust fibre types like the ITU-T G.652.D standard, which are engineered to resist the additional loss caused by physical stress in demanding robotic applications.

The Copper Solution: ETHERLINE® TORSION for Reliable Robot Connectivity

For most robotic applications requiring a copper data link, you need a cable specifically engineered for torsion.

What to Spec:

- ETHERLINE® TORSION Cat.7: Features a special core and conductor stranding that supports ±180°/m torsion. It is tested to very high cycle counts, and its SF/FTP shielding preserves EMC integrity even under constant twisting.

- ETHERLINE® TORSION Cat.6A: Offers variants tested to over 1 million torsion cycles at ±180°/m, protected by oil and abrasion‑resistant PUR jackets.

Why It Matters: The torsion-optimised stranding and robust shielding allow the cable to twist as a single unit without distorting the sensitive twisted pairs inside. This protects the 100 Ω performance and keeps return loss within specification, ensuring a stable data link.

Where to Buy (LAPP eShop Indonesia):

- ETHERLINE® TORSION Cat.7: https://eshop.jj-lapp.com/jjlappindonesia/en/Products/Ethernet-Cables/Cat-7/Ethernet/ETHERLINE-TORSION-Cat-7/p/515575

- ETHERLINE® TORSION Cat.6A: https://eshop.jj-lapp.com/jjlappindonesia/en/Products/Ethernet-Cables/Cat-6A/Ethernet/ETHERLINE-Torsion-Y-CAT6A-4X2XAWG24-7/p/457163

Quick Comparison:

| Feature | Standard Ethernet Cable | ETHERLINE® TORSION Cat.7 | Why it Matters for a Robot |

| Internal Structure | Simple twisted pairs | Bundled pairs with low‑friction fleece wrapping | Bundle twists smoothly as one unit so pairs don’t deform → stable impedance |

| Shielding | Standard foil/braid | Optimised braid angle + wrapping | Maintains shield coverage under twist → consistent EMC |

| Performance | Rated for static/light flex | Tested at ±180°/m for millions of cycles | Sustains link quality under continuous torsional stress |

Note: Exact test values vary by product; always confirm specifications in the current datasheet

The Fibre Optic Solution: HITRONIC® TORSION for Harsh Environments

For applications with heavy EMI (e.g., welding cells) or those requiring very high bandwidth, fibre optics are an excellent choice—provided the cable is built for torsional stress.

What to Spec:

- HITRONIC® TORSION: A family of torsion‑resistant Glass Optical Fibre (GOF) cables (including single-mode OS2 and various multimode OM-grades) with robust PUR sheaths. They are designed for high‑torsion use cases like robot dress‑packs and wind‑turbine loops.

Where to Buy (LAPP eShop Indonesia):

- HITRONIC® TORSION OM2: https://eshop.jj-lapp.com/jjlappindonesia/en/p/445241

- HITRONIC® TORSION OS2: https://eshop.jj-lapp.com/jjlappindonesia/en/Products/Fiber-Optic-Cables/Glass-Optical-Fibre-%28GOF%29/Industrial-and-special-applications/HITRONIC-TORSION-8E-9-125-OS2/p/445251

Application Guide: Choosing Between Copper and Fibre for Your Robot

- Choose Copper (ETHERLINE® TORSION): Ideal for most PLC/sensor links and 100 Mb/s industrial protocols like PROFINET and EtherCAT. While Industrial Ethernet allows for channels up to 100m, runs on moving axes should be kept as short as possible.

- Choose Fibre (HITRONIC® TORSION): Best for welding zones with high EMI, long-distance intra‑plant runs, or high-bandwidth machine vision systems.

Pro Tip: If the robot wrist is exposed to weld spatter or extreme heat, use a PUR‑jacketed data cable and add a layer of high‑temperature protective conduit and glands.

FAQ: Torsion-Rated Robot Cables

“Can I just use a high‑quality standard Cat.6A patch cord?” No. Standard patch cords are designed for static installation or light flexing, not for repeated torsional stress. You will eventually encounter return‑loss and crosstalk issues. Always use cables specifically rated for torsion.

“What is the maximum length for a robot cable?” For copper Ethernet, the 100-meter channel limit still applies. Fibre can go much further. However, for any cable in a dynamic dress pack, the run should be as short as practical to minimize mechanical stress and attenuation.“Do connectors matter for robotic applications?” Absolutely. Use industrial-grade M12 D‑coded (100 Mb/s) or X‑coded (GbE) connectors with 360° shielding to ensure a secure connection that resists vibration and EMC interference.

The Bottom Line: Secure Your Robot’s Data Link

In modern robotics and industrial automation, the data link is as critical as the power supply. Stop chasing “ghost” errors and eliminate a common point of failure by specifying a complete torsion‑rated cable system (cable, connectors, and protection).

Browse the ETHERLINE® TORSION and HITRONIC® TORSION series on the LAPP eShop.

Or book a free consultation with a LAPP specialist to optimize your setup: https://jj-lapp.com/contact-us/

Local stock. German quality. Reliably Connecting ASEAN.