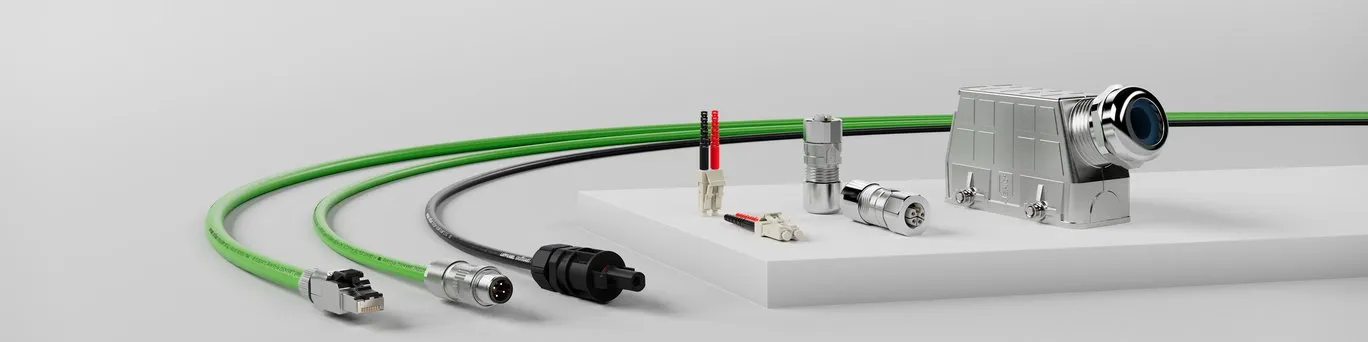

Industrial Connectors Built for Power, Data and Reliability

EPIC industrial connectors engineered for harsh environments, stable power and signal transmission, and fast modular installation.

Browse featured cables

Choose your assembly type and application needs to see parts on the eShop with filters applied.

Connectors – Reliable Industrial

Connections

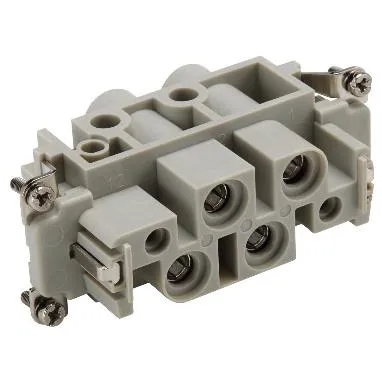

EPIC connectors provide secure, detachable connections for power, signal and data across industrial environments. They are built for fast installation, long service life and consistent performance under demanding conditions. Each connector ensures a stable link that remains secure, aligned and reliably sealed.

Discover Our Connectors

Our connectors enable safe, precise and repeatable connections between cables, devices and control systems. They protect interfaces from environmental influences such as dust, vibration and moisture, ensuring uninterrupted operation. Our product range includes single and multi-pin options, modular inserts, housings and accessories for assembling complete connector systems.

Where Connectors Are Used

01 Power & Control Panels

Reliable power and signal connections for cabinets, drives and industrial control equipment.

02 Machinery & Automation

Secure multi-pin connectors for motors, sensors and modular machine assemblies.

03 Robotics / Harsh Environments

Durable, sealed connectors designed for vibration, movement and demanding industrial conditions.

Which essential requirements must a cable gland meet?