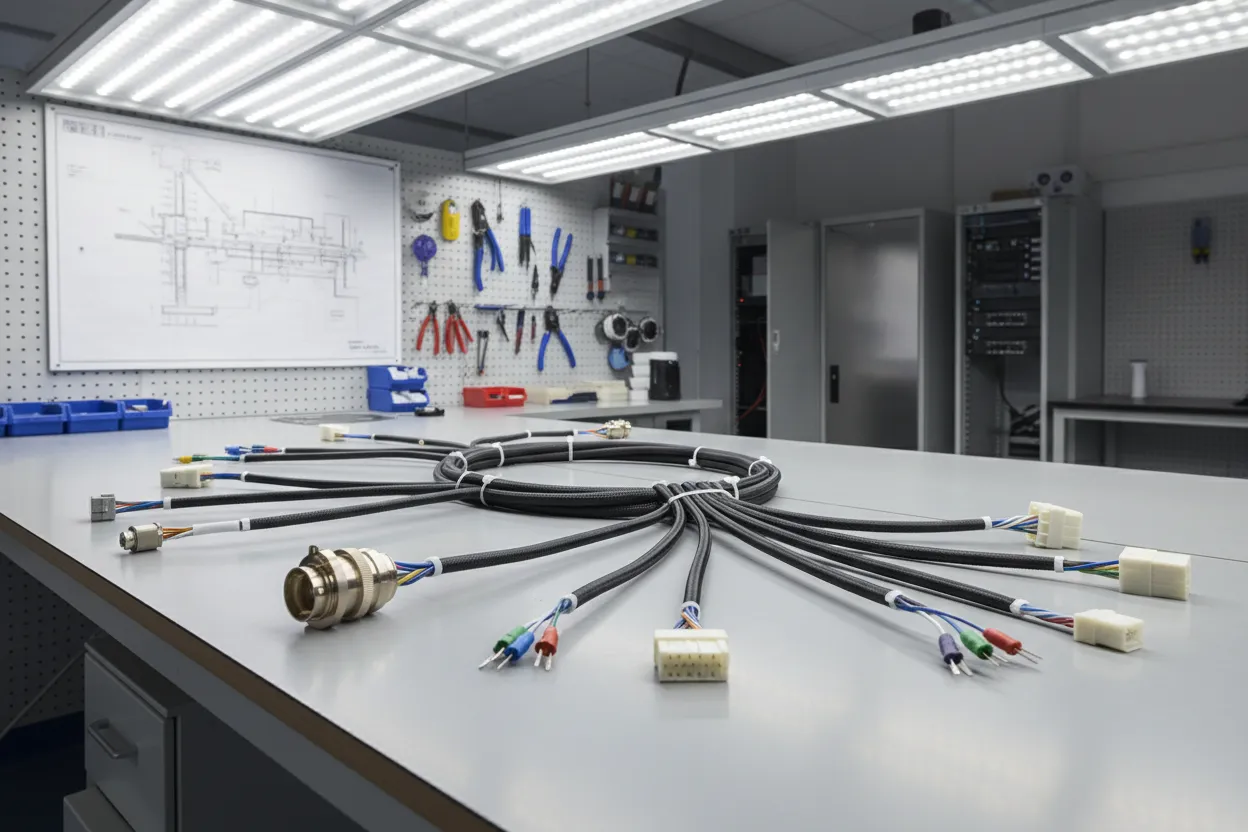

PRE-ASSEMBLED CABLE HARNESSES

System Solutions for Your Machines from LAPP

Reliable, ready-to-install harnesses for modern industries

Pre-assembled cable harnesses reduce wiring time, eliminate on-site variation, and improve system reliability. By outsourcing harnessing to our specialists, you reduce installation errors, speed up production, and lower overall project costs.

Make installation faster and more consistent

Choose from our standard harness assemblies for immediate deployment or work with us on fully customised configurations tailored to your equipment. Every harness is professionally manufactured, tested and prepared for quick integration into your machines or panels.

Where This Solution Is Needed

01 Machine Builders & OEMs

Streamlined harnessing for robotics, conveyors, packaging machines and custom equipment.

02 Control Panels & System Integration

Pre-assembled wiring ensures cleaner layouts, faster cabinet build times and fewer errors.

03 Energy, EV & Infrastructure

Reliable harness sets for EV chargers, power systems and connected infrastructure.

Applications

Discover the right harnessing solution for your machines and applications to ensure fast, reliable and consistent installation.

Robotics & Automation

Challenge:

Multiple sensors, motors, and controllers require consistent, high-quality wiring under continuous motion.

LAPP Solution:

Pre-assembled harnesses with labelled connectors ensure fast installation, reliable routing along robot arms, and reduced wiring errors.

Machine Tools

Challenge:

Heat, vibration, and limited access inside CNCs and industrial machines make manual wiring slow and inconsistent.

LAPP Solution:

Durable, machine-ready harnesses supplied at exact lengths with pre-terminated connectors — reducing setup time and improving long-term reliability.

Conveyors & Gantries

Challenge:

Long runs, repeated flexing, and moving parts require organised, high-reliability harnessing with minimal downtime.

LAPP Solution:

Pre-terminated harness groups with proper strain relief and bend-radius preparation for conveyors, gantries, and material-handling systems.

Cleanroom & Sensitive Areas

Challenge:

Strict contamination rules require clean, low-touch installation and controlled cable handling.

LAPP Solution:

Pre-assembled harnesses reduce on-site cutting and stripping, ensuring cleanliness, consistent quality, and fast deployment.

Why LAPP for Harnessing

Built for Industrial Performance

Pre-assembled harnesses engineered for continuous machine operation with reliable electrical performance, consistent cable routing, and long service life.

Configurable to Your Needs

Choose exact cable types, lengths, labeling and connector configurations to match your machine design and reduce installation time.

Engineered for Safety

Each harness is professionally assembled, strain-relieved and tested to reduce wiring faults, heat issues, and operational risks

Trusted Quality

Manufactured under strict quality control and backed by LAPP’s engineering expertise to ensure long-term reliability.

Durability

Efficiency

Flexibility

Protection

Project-Ready: Standards, Approvals & Delivery

Interoperable by Design

Compatible with automation systems and motion control equipment.

Certified for Performance

Meets international standards for material strength and environmental safety.

Ready to Install

Modular assembly options available for fast installation and maintenance.