PRE-ASSEMBLED CABLE CHAINS

System Solutions for Your Machines from LAPP

Extending the life of cables and wires

is crucial in modern industries

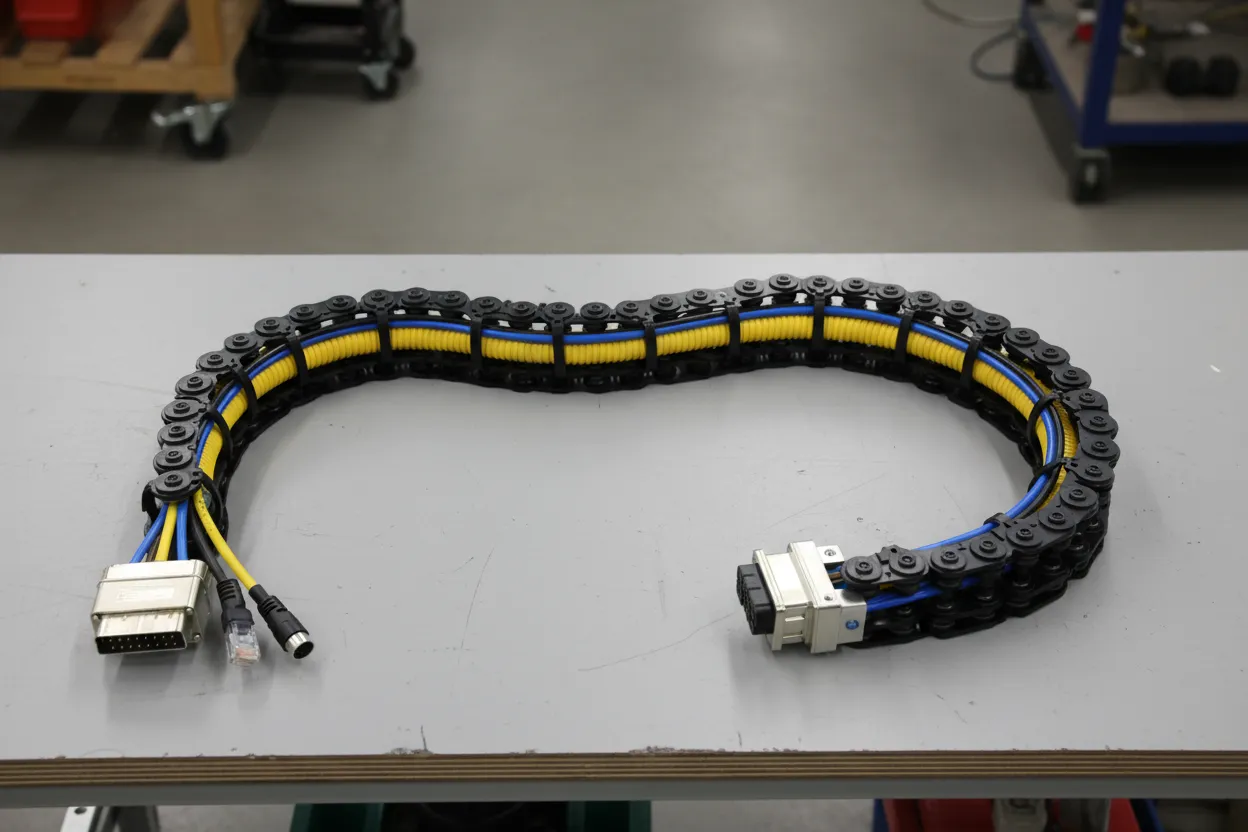

Extending the life of cables and wires is crucial in modern industries. Pre-assembled cable chains and cable chain systems from LAPP protect your cables in moving applications, helping you minimize downtime and enhance productivity. By choosing the right combination of cables and chains—and planning ahead for system usage—you’ll ensure smoother production runs, improved reliability, and reduced maintenance costs.

Make it easy on yourself

select from our standard pre-assembled cable chains for immediate on-site installation or configure your own cable chains with help from our experts. Either way, we deliver custom-fit solutions tailored to your project’s specific requirements. This “plug & play” approach streamlines installation and minimizes disruptions.

Where Cable Chains Are Used

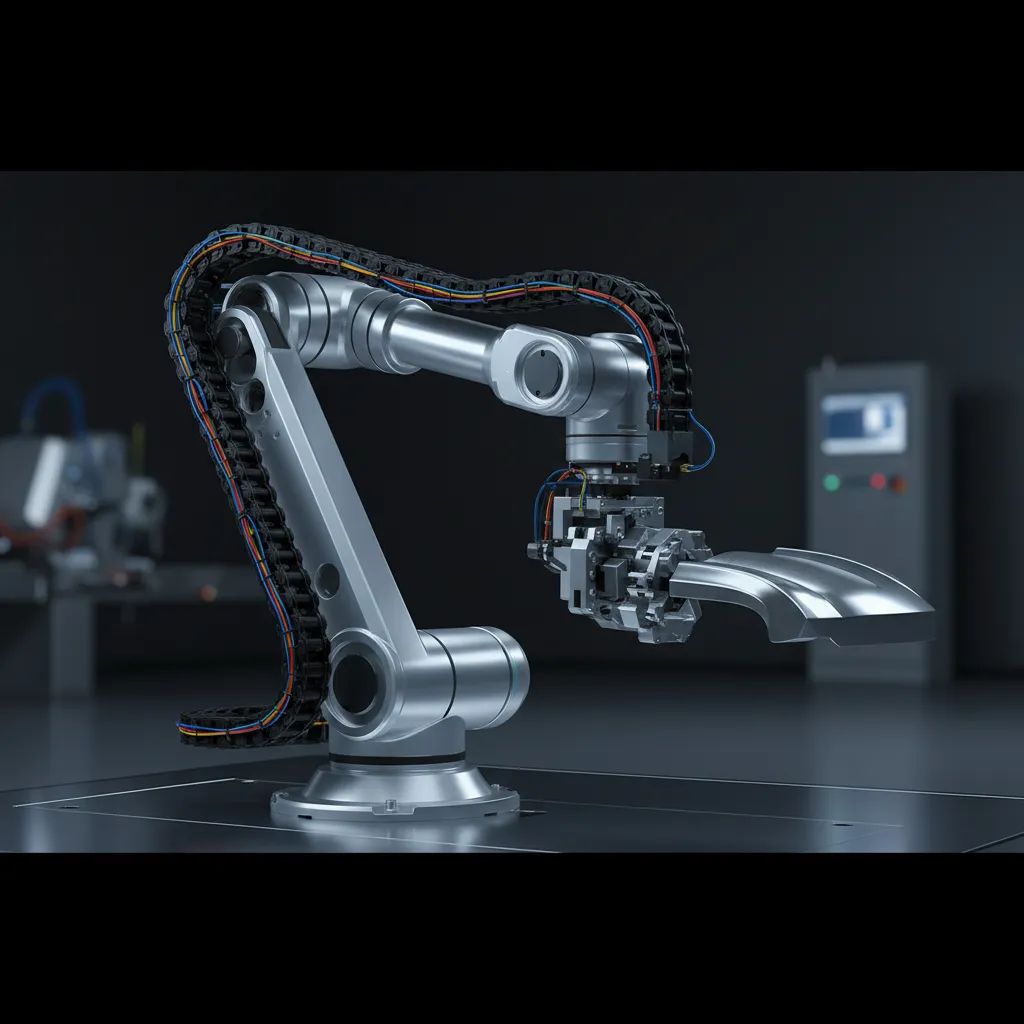

01 Industrial Automation

Keeps cables organized and secure during repetitive motion on production lines and robotic arms.

02 Machine Tools & Equipment

Protects moving cables from oil, chips, and mechanical wear.

03 Conveyors & Material Handling

Maintains continuous power and data flow in long-travel systems.

Applications

Select the right cable chain system for your environment and motion requirements to ensure consistent performance and long cable life.

Robotics & Automation

Challenge:

Constant motion, tight bending radii, and limited space.

LAPP Solution:

Flexible plastic chains with lightweight design and high bending resistance.

Machine Tools

Challenge:

Exposure to oil, metal chips, and heat.

LAPP Solution:

Heavy-duty steel or hybrid chains with sealed links and robust construction.

Conveyors & Gantries

Challenge:

Long travel distances and vibration.

LAPP Solution:

Reinforced chain designs with guiding channels for stable linear motion.

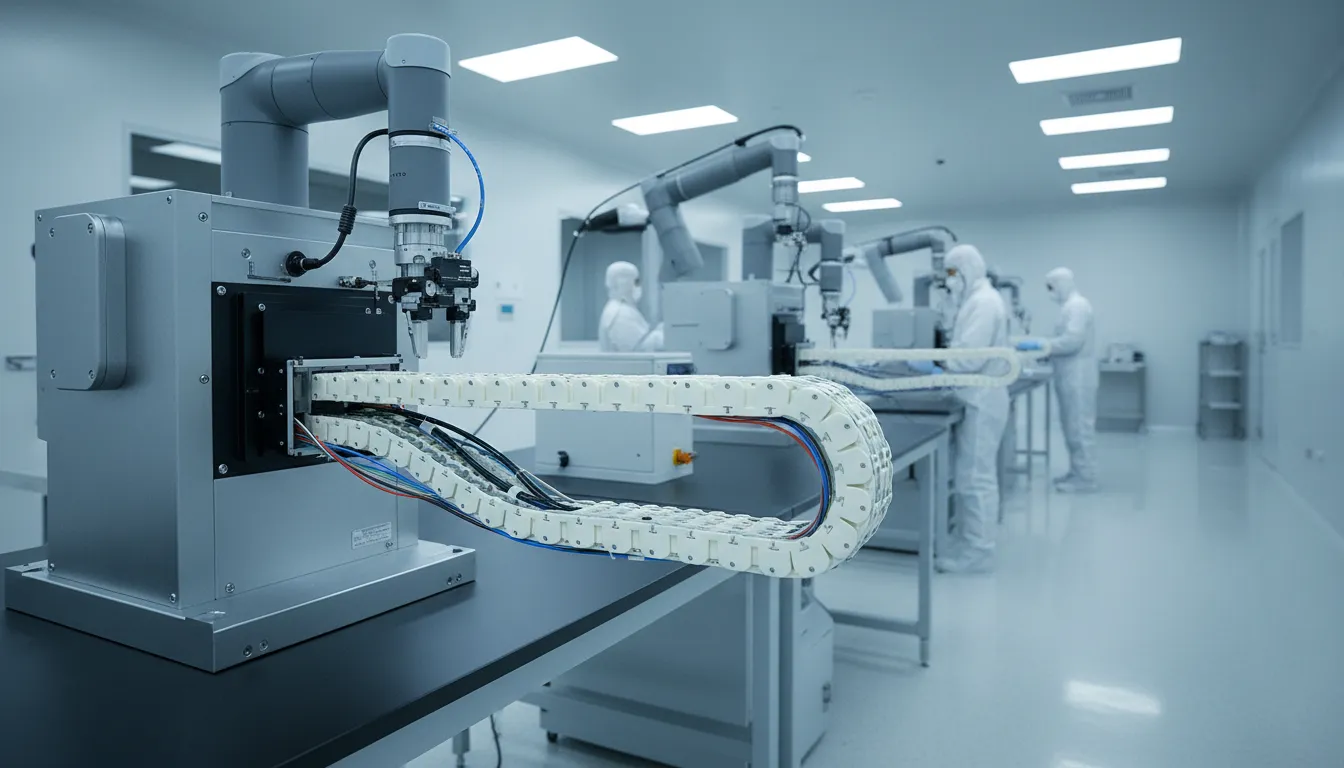

Cleanroom & Sensitive Areas

Challenge:

Dust or particle generation from chain movement.

LAPP Solution:

Low-friction, low-noise plastic chains tested for cleanroom compliance.

Why LAPP for Pre-Assembled Cable Chains

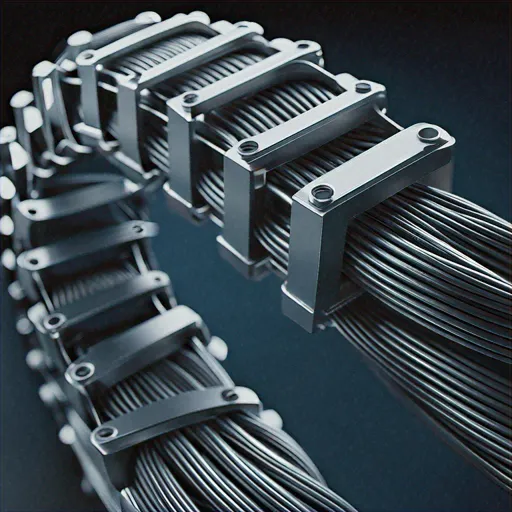

Engineered for Dynamic Motion

Designed for continuous movement with optimized bending radius, strain relief and long service life.

Fast Plug-and-Play Installation

Delivered fully assembled and tested to reduce installation time and minimize machine downtime.

Custom-Configured for Every Machine

Tailored assemblies with the right chain type, cable mix, connectors and lengths for your exact application.

Trusted Quality

Built and tested to perform under vibration, continuous motion, dust, and mechanical stress.

Durability

Efficiency

Flexibility

Protection

Project-Ready: Standards, Approvals & Delivery

Interoperable by Design

Compatible with automation systems and motion control equipment.

Certified for Performance

Meets international standards for material strength and environmental safety.

Ready to Install

Modular assembly options available for fast installation and maintenance.