Reliable Cabling for Harsh Mining Environments

Armoured, UV/oil‑resistant, flame‑rated cables and turnkey harnessing for surface, underground

and site infrastructure.

Overview

Renewable Energy for a Sustainable Mining Future

Mining is among the most energy‑intensive industries. Diesel generators and remote grid connections drive fuel spend, create noise and emissions, and expose operations to supply risks.

By integrating renewable power—especially solar with BESS—sites reduce CO₂, stabilise electricity costs and cut downtime from refuelling.

LAPP makes this transition practical: we supply certified cabling and connectivity for pit, plant and site infrastructure, engineered for UV, oil, abrasion and vibration. Our solutions are proven in extreme climates across ASEAN.

Illustrative benchmarks often used on mine studies: PV LCOE up to ~50% cheaper than diesel; emission reductions up to ~450 g/kWh vs. diesel. Actual results vary by site.

Mining Can Be Divided Into Three Sub‑Areas

Applications

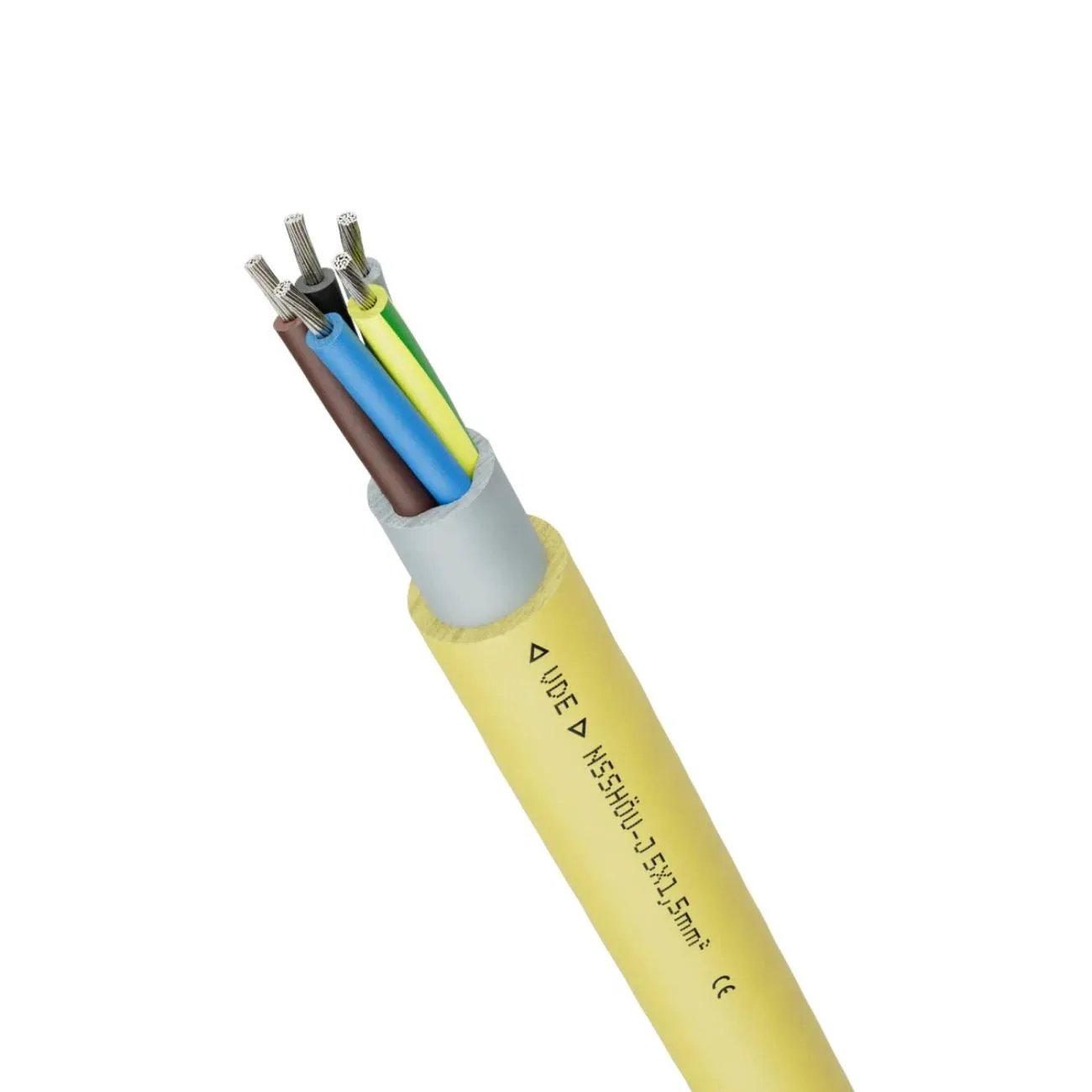

From energy distribution to automation, every station in a mine puts cables under stress: UV, oil, abrasion, vibration, EMI and heat. Choose the right specification to prevent outages. The applications below show typical failure modes and the LAPP product families that solve them.

Why LAPP for Mining

Engineered for Extremes

UV/oil/abrasion‑proof options; armoured, drag‑chain and heat‑resistant designs.

Compliance Ready

IEC/EN/UL; LSZH where required; mining‑grade accessories.

Faster Deployment

Pre‑terminated harnesses, kitting and JIT last‑mile logistics

Lower Lifetime Cost

Fewer failures, longer service intervals and stable supply chains.

Enhanced Efficiency

Optimise operations for smoother, faster performance.

Lower Costs

Reduce operational expenses through streamlined workflows.

Scalability

Flexible solutions designed to grow with your business.

Customer Satisfaction

Ensure accurate, timely fulfilment for happier customers.

Project-Ready: Standards, Approvals & Delivery

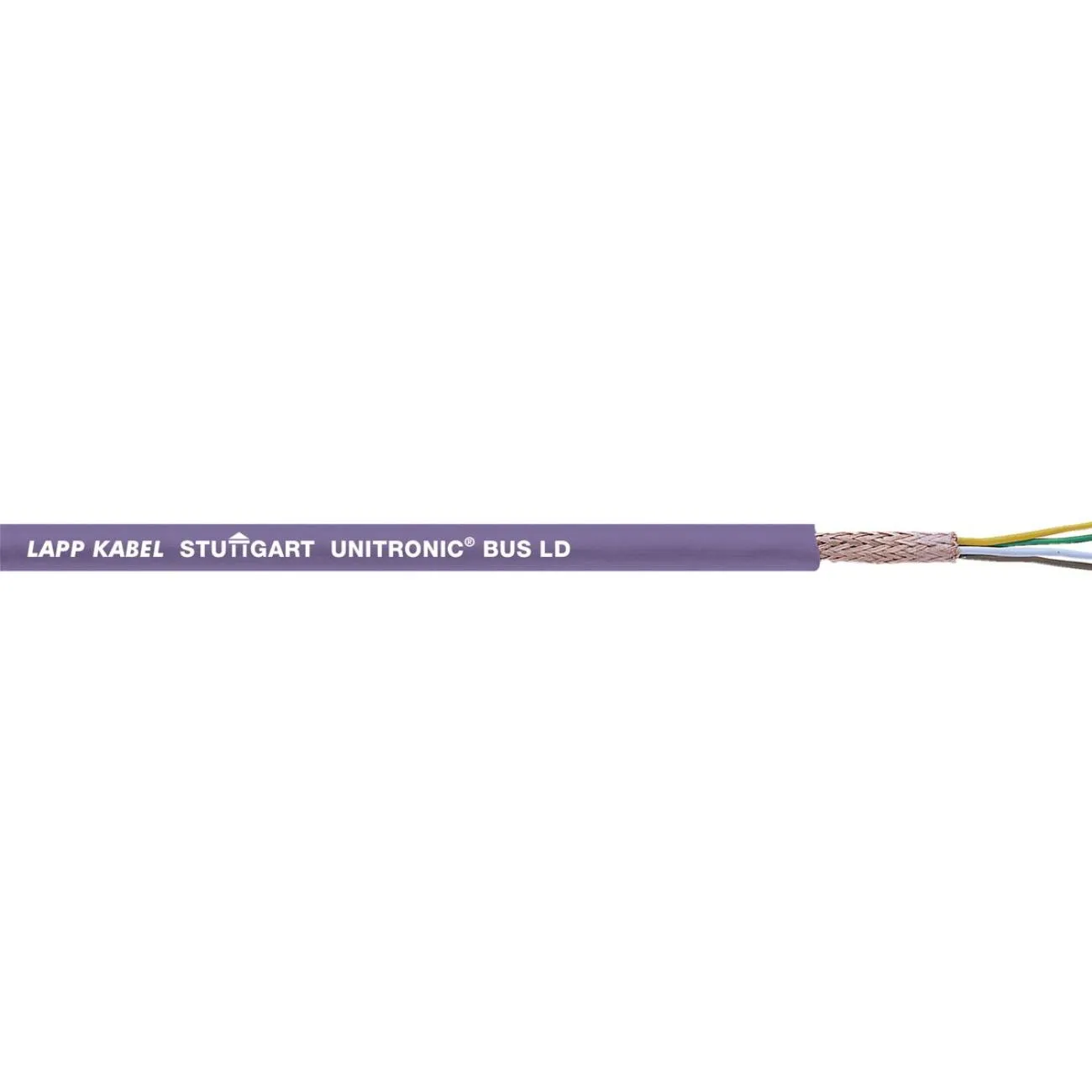

Interoperable by Design

Works across PROFINET, EtherCAT, EtherNet/IP and ASi, so you integrate without lock-in.

Certified for Tough Sites

Options for –40 °C deep-freeze, UL/CSA, CPR (B2ca–Eca) and halogen-free/LSZH.

Plug-and-Play & Last-Mile

Ready-made cable chains and harnessing with just-in-time (JIT) delivery and on-site coordination.